Building diagnostics was one of the first commercial uses of thermography when it became a field in the middle of the last century. Thermal cameras could find a variety of architectural flaws that are unseen to the human eye, even with the limited technologies of the 1960s. By expanding on those initial discoveries, modern thermodiagnostic systems can identify thermal bridges, water leaks, and defective insulation before a structure deteriorates. Let’s examine a few uses for thermal imaging cameras for building inspections.

Determine the heat performance.

Heat loss from pipes, walls, HVAC units, doors, and windows is one of the most prevalent issues in buildings, but fortunately, it’s also one of the easiest to find. While infrared cameras cannot detect air temperature, they can measure the effect of air temperature on certain surfaces, like vent grills. Using this data, one can determine whether there is enough airflow in a given area to distribute heat or coolness.

Thermal imaging is also helpful during a project’s building. For example, taking pictures of the roof and walls to determine whether there are any gaps in the insulation might help you verify that a builder is doing a decent job of insulating a wall.

The comprehensive coverage area of a building inspection camera is one of its many wonderful features. As a result, you are likely to encounter unexpected issues when looking into a specific problem.

Plan for reconstruction and quality control.

Reconstruction plans, quality control, and new building inspections all use infrared technology. Infrared pictures can be used to monitor the drying progress of the building structure to take the appropriate action to expedite the drying process. A quicker building is possible if the drying process is sped up. A thermal imaging camera helps establish whether the building structure is dry before proceeding.

Detect problems in district heating.

Another typical heating method is district heating. This heating system produces heat at a central location to fulfill the heating requirements of homes and businesses. Thermal imaging analysis can help you quickly detect any problems with the underground heating system. An infrared camera can view the heating pipeline even when the ground is covered in snow and ice.

Examine the electrical system.

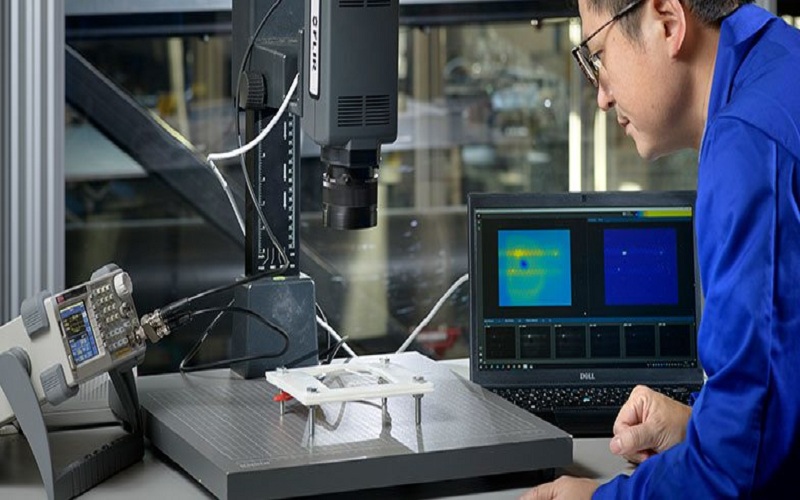

Determining whether every piece of electrical equipment in your facility is operating as intended might be challenging, given its quantity, unless you want to go through every motor and circuit breaker for days on end!Using a thermal inspection camera, you can measure objects from a distance and identify any difficult-to-reach equipment problems.

This technology helps you to see any failed motor bearings or overheating circuits. Failed sections will be noticeably warmer than the surrounding region, allowing you to quickly identify any issues with electrical distribution.These tools can also assist you in locating loose connections since, with time, dirt builds up additional resistance that leads to component overheating. Once more, the thermal imaging camera will detect this, and it is possible to address the problem before the system collapses.

Locate a thermal bridge.

Thermal bridges are places where building construction—such as metal fasteners, concrete slabs, beams, or columns—provides less insulation. Heat will try to leave the area with a higher temperature using the most accessible route (the path of least resistance). The heat is frequently “short-circuited” through an element with higher thermal conductivity than the surrounding material. We refer to this part as a thermal bridge. An infrared thermal camera helps clearly show the thermal bridge’s presence.

Detect roof leaks

Using thermography, roof experts can assess the state of a roof and spot issues before they get worse. Perforations, damaged roofing underlay, and missing tiles are familiar sources of roof leaks. As a result, moisture will heat up during the day as the sun shines, causing the insulation above the ceiling to become saturated. The roof will radiate heat at night, but because the parts storing moisture have a larger thermal mass, they will take longer to release.

These spots are detectable using a thermal imaging camera. This allows quick roof repairs to improve the insulation. Since the precise issue region has been identified, the entire roof doesn’t have to be replaced, saving a ton of money, time, and hassle.

Find gas leaks

Finding gas leaks through the building’s exterior construction is standard procedure. Gas leaks result in increased energy losses, typically leading to ventilation system issues and condensation inside the structure, which worsens the indoor climate. However, it is easy to identify the common occurrence of cold air leaks from a building using thermal imaging cameras.

Identify solar system issues.

The most crucial aspect of a solar panel installation is its efficiency. Solar energy systems are meant to work with renewable energy sources, like sunlight, and convert it into energy through complex photovoltaic installations. Correct solar system installation can mean the difference between saving a lot of money and wasting money on a broken system.

It’s simple to identify enigmatic, hot patches developing on solar modules or panels using a thermal imaging camera to assess the solar panel installation, including the solar modules. Hot patches indicate a problem with the system, and the solar PV system’s efficiency can be lower. However, detecting these problems early makes it possible to find solutions before they worsen.

Simplify structural maintenance

Infrared thermal imaging offers essential information when restoring structures and monuments. The infrared view makes the frame structure buried in the mineral plaster more evident. Consequently, assessing the utility of these structures’ exposure is possible. Separating the gypsum on the wall as soon as possible is feasible to allow for maintenance actions.

The bottom line

Building surveyors can perform a wide range of building analyses quickly and without causing any harm to the surrounding area, thanks to the adaptability and capabilities of thermal cameras. They help contractors and surveyors identify structural issues that are invisible to the naked eye. This contrasts with other types of meters, like moisture meters, which need to slightly damage materials to obtain readings.